193nm

Mirrors

Output Couples and Lenses

Variable Attenuators

Technical Data of standard ArF Laser Components

Window

Mirrors

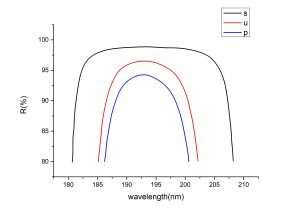

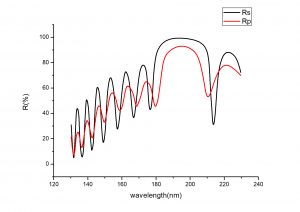

Turning Mirror [Coating on CaF2 UV-grade, Angle of Incidence=45°, Polarisation : u,s,p-Pol. HRu ( 45°, 193nm) > 95%, HRs ( 45°, 193nm) > 97%, HRp ( 45°, 193nm) > 93%]

|

| Reflection Spectrum |

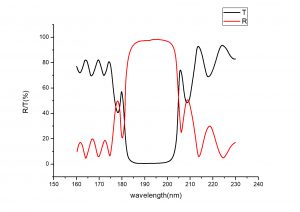

Laser Mirror [ Angle of Incidence=0°, Polarisation : u-Pol]

|

| Reflection &Transmission Spectrum |

- All fluoride systems guarantee high reflectance and high damage thresholds.

- High quality mirror substrates, windows and lenses of CaF2 (193 nm excimer grade, HELLMA Materials GmbH) and fused silica.

- Development and production of customer specific components such as beam splitters and variable attenuators on request.

Protected Aluminum Mirror

|

| Reflection Spectrum |

Enhanced Aluminum Mirror

|

| Reflection Spectrum |

- Enhanced aluminum mirrors:

- Rp > 93%

- Rs > 98%

- Ru > 96%

- For more information on aluminum mirrors see pages 96 – 97 in catalog.

Output Couples and Lenses

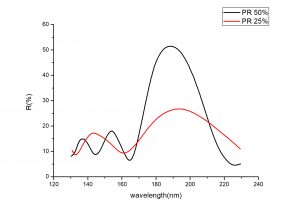

Output Coupler [Angle of Incidence=0°, Output coupler with R (0°, 193 nm) = 50 % ± 3 % and R (0°, 193 nm) = 25 % ± 2 % (back side uncoated)]

|

| Reflection Spectrum |

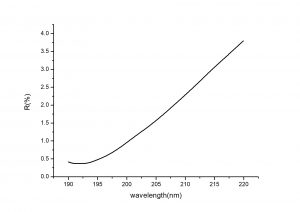

Output Coupler [Angle of Incidence=0°, CaF2 window coated on both sides with a fluoride AR coating for 193 nm]

|

| Reflection Spectrum |

- PR coatings with tolerances of

- ± 2 % for R = 10 % … 30 %

- ± 3 % for R = 30 % … 75 %

- ± 2 % for R = 75 % … 90 % and

- ± 1 % for R > 90 %.

- Single wavelength AR coating with residual reflectance values of

- R < 0.25 % at AOI = 0° and

- R < 0.6 % at AOI = 45° (unpolarized light).

- Broadband and multiple wavelength AR coatings.

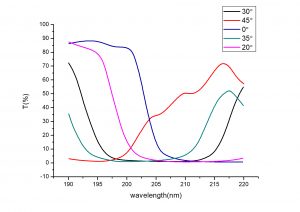

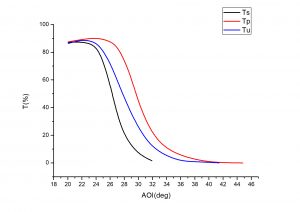

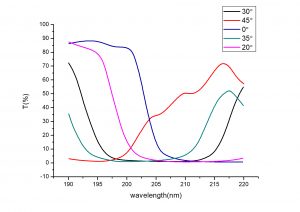

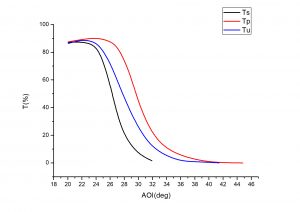

Variable Attenuators

|

|

| Transmission Spectrum | |

- Attenuators with custom transmittance ranges on request.

- Attenuators can be delivered with AR coated compensation plates of CaF2 or fused silica.

Technical Data of standard ArF Laser Components

| Coating | Substrate | Damage threshold* | Lifetime test |

| Fluoride coatings | |||

| AR (0°, 193nm) R < 0.25% | CaF2 | 4 – 5 J/cm2 | 2.5 x 108pulses, no damage** |

| AR (0°, 193nm) R < 0.25% | fused silica | 2 – 3 J/cm2 | |

| PR (0°, 193nm) R = 25% | CaF2 | 3 – 4 J/cm2 | 2.5 x 108pulses, no damage** |

| PR (0°, 193nm) R = 50% | CaF2 | 2 – 3 J/cm2 | 109pulses*** |

| HR (0°, 193nm) R > 96% | CaF2 | 2 – 3 J/cm2 | 109pulses***, no damage |

| 1010pulses****, no damage | |||

| 4 x 109pulses*****, no damage | |||

| HR (45°, 193nm) R > 95% (random polarized) | CaF2 | 2 – 3 J/cm2 | |

| Oxide coatings | |||

| HR (0°, 193nm) R>92% | fused silica | <1 J/cm2 |

- 1000 – on -1, 14 ns; measurements were performed at Laser Labor Göttingen and at Friedrich-Schiller-Universität Jena

- Energy density: 18 mJ/cm2, repetition rate: 4 kHz, pulse duration: 30 ns; tested at COHERENT AG, Göttingen

- Energy density: 55 mJ/cm2, repetition rate: 1 kHZ, pulse duration 15 ns; tested at COHERENT AG, München

- Energy density: 27 mJ/cm2, repetition rate: 4 kHz, pulse duration: 30 ns; tested at COHERENT AG, Göttingen

- Energy density: 80 mJ/cm2, repetition rate: 1 kHz, pulse duration: 12 ns; tested at COHERENT AG, München

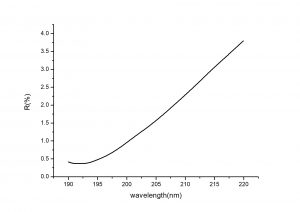

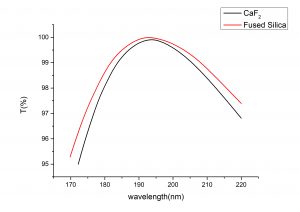

Window

[Angle of Incidence=0°, Coating on CaF2 193nm excimer grade/Fused Silica 193nm excimer grade AR(0°, 193nm)<0.25%]

|

| Transmission Spectrum |