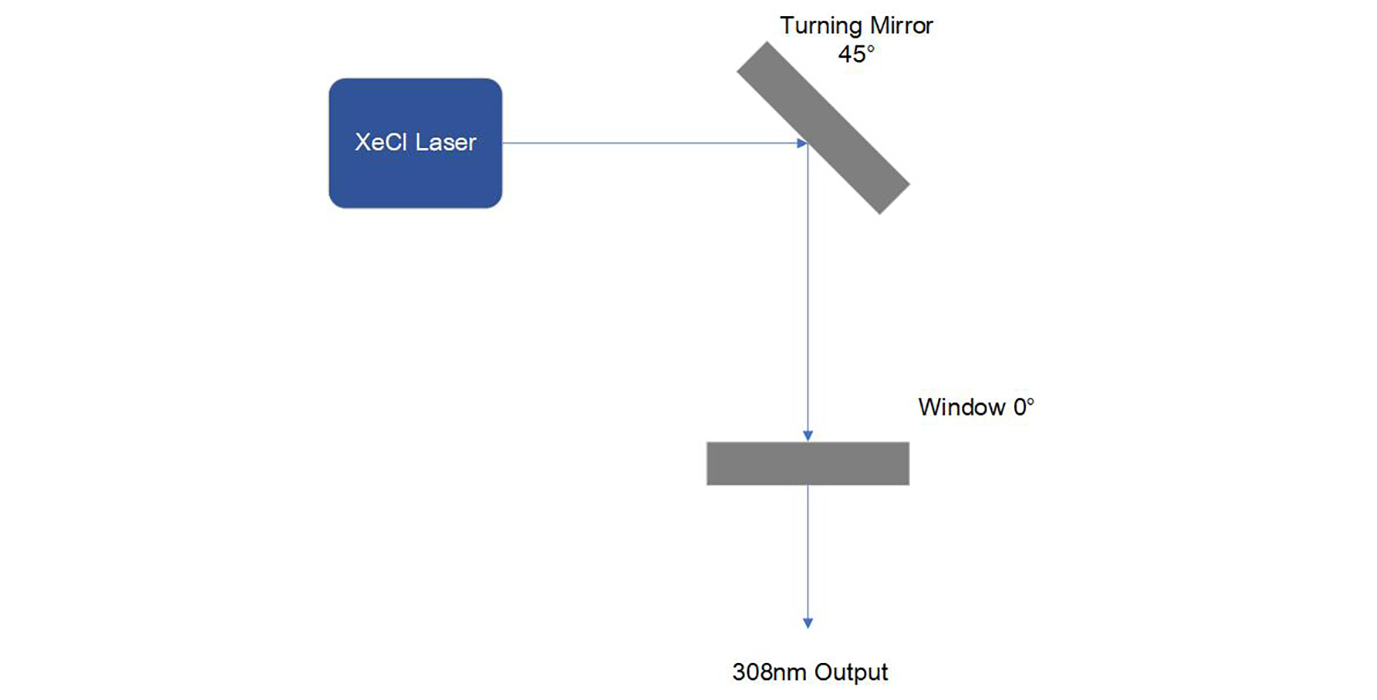

308nm

Cavity Mirrors

Output Couplers

Windows and Lenses

Turning Mirrors

Attenuators

Technical Data of XeCl Laser Components

Window

Cavity Mirrors

|

- Oxide coatings for high mechanical stability.

- Coatings can be produced by IAD, magnetron sputtering or IBS.

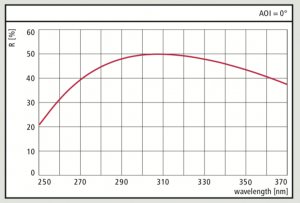

Output Couplers

|

- PR coatings with tolerances of

- ± 2 % for R = 10 % … 30 %

- ± 3 % for R = 30 % … 75 %

- ± 2 % for R = 75 % … 90 % and

- ± 1 % for R > 90 %.

Windows and Lenses

|

- High quality mirror substrates, windows and lenses of fused silica.

Turning Mirrors

|

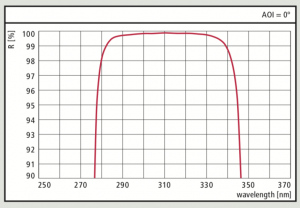

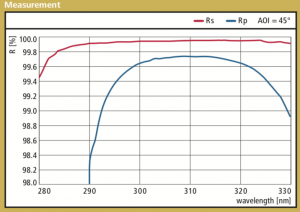

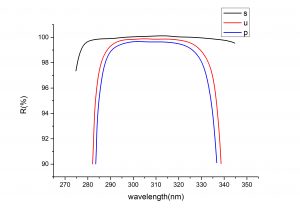

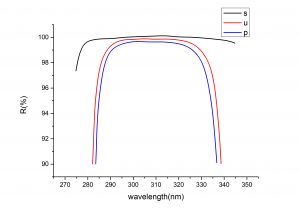

Turning Mirror [ Angle of Incidence=45°, Polarisation : u,s,p-Pol. HRu ( 45°, 308nm) > 99.5%, HRs ( 45°, 308nm) > 99.9%, HRp ( 45°, 308nm) > 99.5% ]

|

| Reflection Spectrum |

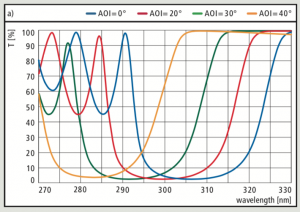

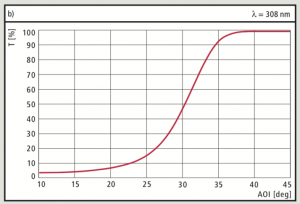

Attenuators

|

|

|

Technical Data of XeCl Laser Components

| Coating | Materials | Reflectance | Lifetime test |

| HR (0°, 308 nm) | fluorides | R > 98 % | 2 x 108 pulses *** |

*** Energy density: 55 mJ / cm2, repetition rate: 100 Hz, pulse duration: 15 ns; tested at COHERENT AG, München

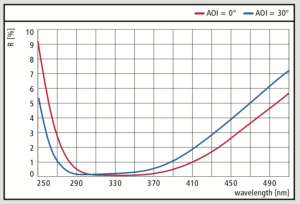

Window

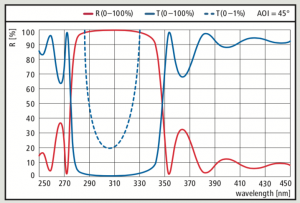

Angle of Incidence=0°, Coating on Fused Silica 248nm excimer grade AR(0°, 308nm)<0.25%.

|

| Transmission Spectrum |